Product Details

1.No stress: the special vehicle cooperates with laser processing, even if the component; 2.Accurate thermal impact control: select the appropriate laser type according to different thermal impact requirements and cooperate with the appropriate laser processing parameters to minimize the thermal impact; 3.Cleaning processing: laser soot treatment is carried out in real time during processing to minimize the impact of soot on components; 4.Multi function: it is not only suitable for precision cutting and drilling of soft plate, hard plate and soft hard combination plate of various thicknesses, but also suitable for cutting and drilling of other materials, such as glass, ceramics, thin metal plate, etc; 5.Safety: the processing area is completely closed to ensure the safety protection of the processing process, which conforms to the electrical standard design of China and the European Union; 6.Automation: open ports are reserved to facilitate the adaptation of power control system, automatic loading and unloading system and MES system to meet various automation needs; 7.High speed and high precision: high speed and high precision X / Y / Z mobile system, perfect precision compensation mechanism, including single axis precision compensation, plane precision compensation and scanning area precision compensation. The motion control system is equipped with contract axis CCD positioning system to ensure high speed and high precision in the processing process; 8.High degree of freedom: a variety of nanosecond, picosecond UV and green lasers are available to meet different needs; 9.Simple and fast operation: the software interface is simple, compatible with the conventional data format of the industry, and the operation is simple; 10.Power detection system: optional power online detection system to ensure stable power and consistent cutting quality. Our advantages: 1.We have a high tech team who can provide a series of professional technical support for our customers; 2.We are professional SMT&DIP machine factory in China for over 20 years; 3.Strict QC System. We will check two times with your orders. The first time is during mass production and the second time is prior to shipment. We will check each and test machine before shipment. 4.Competitive price. You can get a competitive price from here. Our price is factory price. Our purpose: customer oriented, quality first. 5.All machine size is customized,provide Non-standard service; We sincerely hope to work together with every client, to build the long-term business and friendship. Believe in us, Believe in professional!

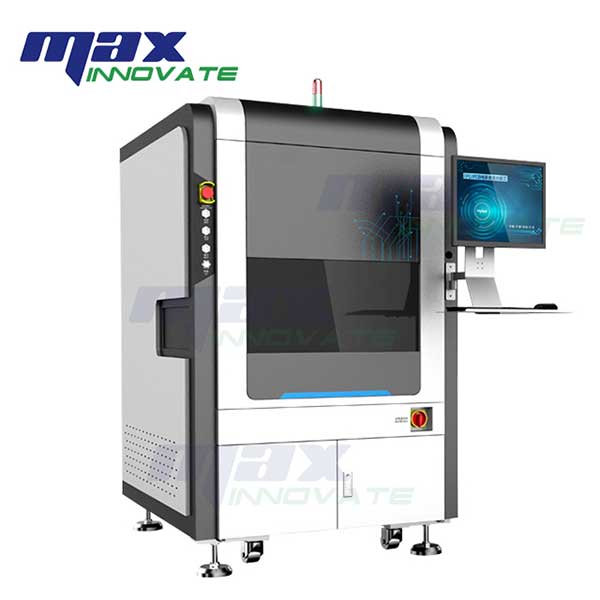

Specifications

| ModelLC-3220-C | Dimension1030*1280*1650mm | Max. work range350*300mm |

| X / Y axis movement resolution0.5um | Galvanometer resolution2um | Repeat positioning accuracy≤±2um |

| Cutting accuracy±20um | Maximum average laser output power15W | Accept data formatGerber,DXF |

| Laser wavelength355mm, diode pumped solid state laser | Laser pulse frequency20kHz-150kHz | WeightApprox. 500KGS |

| Power220V+N+PE,50HZ,3.5KW | Main power3.0KW | Auxiliary equipment power1.5KW |

| External air source0.4-0.6Mpa | Laser10W/15W/20W/30W optional | BrandMax Innovate |

Key Features

Accurate thermal impact control

Automatic loading and unloading system and MES system

UV and green lasers are available

SMT&DIP machines factory in China! Good quality,Good serive, competitive price!