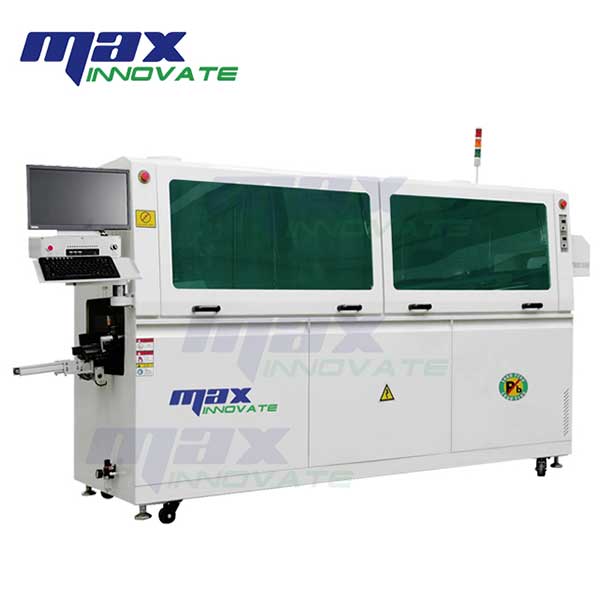

Product Details

1. Appearance design: new design , plastic spraying process, no paint falling off, durable.

2. Hot air preheating: no blind area, high-efficiency heat conduction; Thick insulation layer, power saving and energy saving.

3. Alloy chain claw: high strength and long lifespan.

4. Adjustable nozzle design: the wave crest can be adjusted according to the width of PCB, which greatly reduces the oxidation of tin when welding PCB small plates.

5. Transmission mechanism: precision modular design, accurate transmission, long service life and easy maintenance.

6. Transportation system: closed loop control. Stepless speed regulation to accurately control PCB preheating and welding time.

7. Heating system: the temperature adopts PID closed-loop control, and the temperature control is stable and reliable.

8. Flux spray device: stepper motor closed loop automatic tracking spray system, spray width and spray time automatically adjust, and can be set as required and advance and prolong the spray time; Isolation design, pull-out and detachable, easy for cleaning and maintenance;

9. Control system: intelligent control program and brand electrical appliances are adopted to ensure the stable operation of the equipment.

10. Machine interface: brand computer is adopted to ensure the reliability and stability of the system.

Our advantages:

1.We have a high tech team who can provide a series of professional technical support for our customers;

2.We are professional SMT&DIP machine factory in China for over 20 years;

3.Strict QC System. We will check two times with your orders. The first time is during mass production and the second time is prior to shipment. We will check each and test machine before shipment.

4.Competitive price. You can get a competitive price from here. Our price is factory price. Our purpose: customer oriented, quality first.

5.All machine size is customized,provide Non-standard service; We sincerely hope to work together with every client, to build the long-term business and friendship. Believe in us, Believe in professional!

Specifications

| Model SE-350 | PCB workingrange Max.50~300mm | PCB transportheight 750±50mm |

| PCB transportspeed 0~2000mm/Min | PCB transportangle(Weldinginclination) 3~7° direction | PCB transport L→R/R→ optional) |

| Wave quantity 2 | Preheatingzonelength 500*3=1500mm | Preheatingzone quantity 2 |

| Preheatingzone power 3.5*3=10.5kw | method Heating Hot air | Tin furnacepowe r 11KW |

| capacity Solder pot Approx.300kg | Machinecontrol method PLC+PC | capacity Soider flux Max5.2L |

| Air source 4~7KG/CM2 | Diemensions L3500xW1250xH1700mm | Weight Approx1000kg |

Key Features

High production efficiency

PLC+ PC control

Titanium finger transport,rail width is adjustable

Longer preheating zones

SMT&DIP machines factory in China! Good quality,Good serive, competitive price!