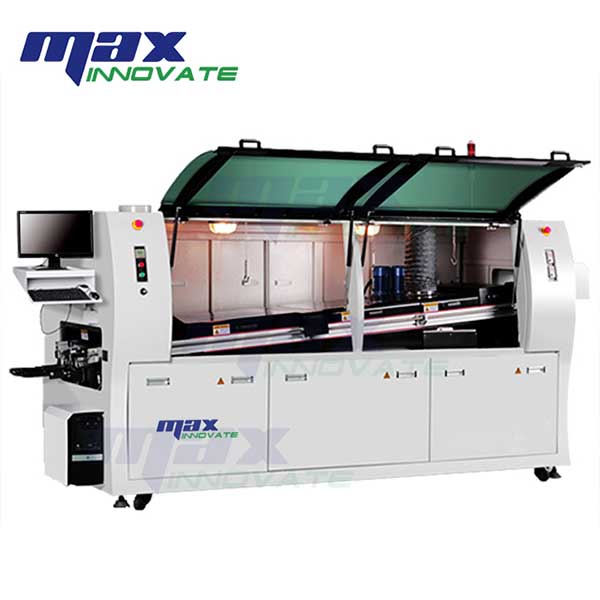

Product Details

1.Open type streamline shell design, beautiful appearance, easy to clean up.

2.The solder furnace is made of alloy material. High strength and high hardness special aluminum alloy guide, long service life.

3.The touch screen/PC + professional PLC control technology is used to ensure the reliability and stability of the system.

4.Step spray device, can be automatically adjusted with the width of PCB, effectively saving the economic process.

5.Tin wave peak adopts electronic stepless frequency control, independent control of wave height.

6.Isolation device, flux smoke from the exclusive exhaust and recovery channels to meet the environmental requirements.

7.Users can automatically set the date, time, temperature control parameters of the automatic switchgear.

8.Micro chemical pump, propanol cleaning agent, automatic circulation cleaning chain claw.

9.The three section of independent preheating, hot wire device, fully stimulate the activity of flux, and get good welding effect. The heat is directly radiated to the bottom of the PCB plate, and the heat is fast and the service life is long.

Our advantages:

1.We have a high tech team who can provide a series of professional technical support for our customers;

2.We are professional SMT&DIP machine factory in China for over 20 years;

3.Strict QC System. We will check two times with your orders. The first time is during mass production and the second time is prior to shipment. We will check each and test machine before shipment.

4.Competitive price. You can get a competitive price from here. Our price is factory price. Our purpose: customer oriented, quality first.

5.All machine size is customized,provide Non-standard service; We sincerely hope to work together with every client, to build the long-term business and friendship. Believe in us, Believe in professional!

Specifications

| Model SE-350 | Dimensions 3200*1200*1650mm | Power 3P 380V |

| Weight Approx. 600kgs | Power for solder tim stove 11KW-16.5KW | PCB transport height Max. 760±20mm |

| PCB transport direction L-R or R-L (optional) | PCB transport speed 0-2.0mm/min | PCB working width 0-350mm |

| Conveyor method Titanium finger | Solder flux capacity 5L | Preheating zone length 1500mm |

| Power for preheating 7.5KW | Solder volume 280-300KGS | Solder type Lead-free solder/ordinary solder |

Key Features

High production efficiency

PLC+ PC control

Titanium finger transport,rail width is adjustable

Longer preheating zones

SMT&DIP machines factory in China! Good quality,Good serive, competitive price!